Working

It works on energy conversion system where a MG set with conventional 415V, 50Hz, 3ph input, and a output of 200V, 300Hz is achieved. This output is fed to the hand held power tool.

- Virtually no loss of rated power during full load grinding

- High efficient output

- Continuously constant torque

- More simpler and stronger construction of the motor

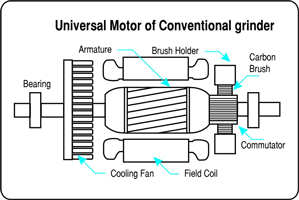

- No armatures, field coil, carbon brushes and no maintenance

- Low operating and energy cost

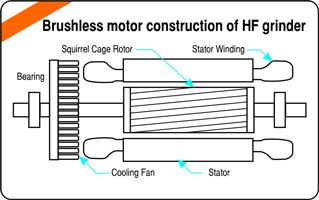

- Motor consist of stator and rotor, rotor is squirrel cage and stator has winding which is stationary so no rotating winding in the motor

- Speed drop is between 3 to 5% so higher cutting speed and 30% more productivity

- No fear for theft as it cannot run without suitable convertor

Salient Feature

Comparison Chart

S.No. |

Part No. |

Haller |

Conventional |

| 1 | Armeture |  |

|

| 2 | Feild Coil |  |

|

| 3 | Carbon Brush |  |

|

| 4 | Speed Drop | 5% | 30% |

| 5 | Torque | Constant | Drop with Speed |

| 6 | Maintains | Lowest Maintenance Confined to Bearing Only |

High Maintenance Since more Frictional Parts |

| 7 | Input Power | 3ph. 300 Hz 200 V From Special Power Source |

Ac 50 Hz 220 V General Power Source |

Converter |

Angle Grinder |

Drilling Machine |

| 3.7 Kw | 1 Kw Grinder / Sander | 0.5 Kw, 24mm |

| 5.5 Kw | 1.5 Kw | |

| 7.5 Kw | 2.2 Kw Grinder / Sander | |

| 9.3 Kw | 3.7 Kw | |

| 15 Kw |

Chart showing required convertor according the choice of power tools.

Note : All the power tools & converter are made to order, pictures shown are for indication purpose, actual models may vary.